Services

Turnkey Project

Turnkey Project Services A turnkey project in automation refers to a comprehensive solution where a contractor or service provider manages the entire process of designing, implementing, and delivering an automated system. The client receives a fully operational system with minimal involvement, as the contractor handles everything from initial planning and design to installation, testing, and training.

- Special Purpose Machine for dedicated application.

- Robotics Solution.

- Autoloader & Unloader for Press.

- Pick & Place.

- Secondary Packaging Solution.

- Process Control.

- Furness Control.

- Conveyor Automation.

- Conveyor and Material Handling.

- Endline Packaging Solution.

- Palletizer machine.

Control Panel Reconditioning Service

Control Panel Reconditioning Services focus on restoring, upgrading, and modernizing existing industrial control panels to improve functionality, safety, and reliability. Control panels are vital components in automated systems, managing power distribution and controlling equipment in various industries such as manufacturing, power generation, water treatment, and more. Reconditioning services aim to extend the life of these panels and bring them up to modern standards without the need for complete replacement.

Key Aspects of Control Panel Reconditioning Services:

- Inspection and Assessment

- Component Replacement

- Wiring and Cable Management

- Control System Upgrades

- Power Management

- Safety and Compliance

- Environmental Protection

- Control Panel Modernization

- Testing and Commissioning

- Documentation and Training

PLC Programming For Industrial Automation

PLC Programming for Industrial Automation involves designing, developing, and implementing control programs for Programmable Logic Controllers (PLCs) to automate machinery, processes, and production lines. PLCs are widely used in various industries, such as manufacturing, oil and gas, food and beverage, and automotive, due to their reliability, robustness, and flexibility in controlling automated systems.

PLC programming enables the automation of tasks like machine operations, process control, conveyor systems, and safety systems, improving productivity, consistency, and safety in industrial environments.

Key Elements of PLC Programming for Industrial Automation

- Understanding the Process or Machinery

- Programming Languages

- Program Structure

- Input/Output (I/O) Configuration

- Communication and Networking

- Timers, Counters, and Comparators

- PID Control

- Alarming and Error Handling

- Simulation and Testing

- Safety and Compliance

- Maintenance and Troubleshooting

Scada Programming Service

SCADA Programming Services (Supervisory Control and Data Acquisition) involve the development, configuration, and implementation of SCADA systems that monitor and control industrial processes. SCADA systems are essential for industries where real-time data acquisition and control of equipment are critical, such as manufacturing, energy, water treatment, oil and gas, and utilities. SCADA allows operators to monitor and control multiple processes from a central location, improving efficiency, safety, and decision-making through real-time data visualization and control.

Key Components of SCADA Programming Services

- System Design and Architecture

- PLC and RTU Integration

- Data Acquisition and Tag Configuration

- HMI Development

- Alarm Management and Notification

- Data Logging and Historian Setup

- Control Logic Implementation

- Report Generation

- Network and Security Configuration

- Testing and Commissioning

- Maintenance and Support

HMI Programming Service

HMI Programming Services HMI (Human-Machine Interface) programming involves designing and developing the interfaces that allow humans to interact with machines, typically in industrial environments such as manufacturing, automation, and control systems. HMIs provide visual representations of machine processes, equipment statuses, and control mechanisms, allowing operators to monitor and control systems efficiently.

Key Components of HMI Programming Services

- User Interface for Machine Control

- Data Visualization

- System Monitoring and Control

- Integration with Automation Systems

- Alarm Management and Notification

Servo Based Automation Service

Servo Based Automation Service Servo-based automation uses servo motors coupled with feedback systems (like encoders or sensors) to control machines’ position, velocity, and torque. These systems are ideal for applications requiring precision and flexibility, such as robotics, CNC machines, packaging equipment, and automated manufacturing lines.

Key Components of Servo Based Automation Service

- Precision Motion Control

- Real-Time Feedback

- Energy Efficiency

- High-Speed Performance

- Customization

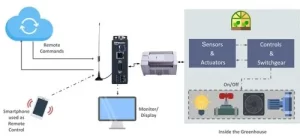

Industry 4.0 Solution Services

An Industry 4.0 Solution Provider delivers technologies, services, and strategies to help businesses implement the principles of Industry 4.0. This term refers to the fourth industrial revolution, which focuses on the digitization and interconnectivity of manufacturing processes, driven by advancements in automation, data exchange, and smart technologies. The goal of Industry 4.0 is to create “smart factories” that are highly efficient, adaptive, and integrated.

Industries Benefiting from Industry 4.0 Solutions:

- Manufacturing: Automating and optimizing production lines, supply chains, and inventory management.

- Automotive: Smart factories with AI-powered robots, predictive maintenance, and real-time production monitoring.

- Energy and Utilities: Monitoring and optimizing energy consumption, managing grids, and improving the efficiency of power plants.

- Aerospace: Advanced robotics, additive manufacturing, and real-time quality control to improve production.

- Healthcare: Smart devices and IoT technologies that improve logistics, manufacturing of medical devices, and patient care.

Panel Reconditioning

Panel reconditioning refers to the process of refurbishing and upgrading electrical panels to restore their functionality, safety, and efficiency. This process is essential for maintaining older equipment or adapting it to modern standards.Enhances the operational life of electrical panels.Allows integration of newer technologies and components.Thorough assessment of the panel’s condition, including wiring, components, and physical structure.Conducting functional tests to ensure the panel operates correctly after reconditioning.

- Extend Lifespan

- Upgrade Technology

- Component Replacement

- Wiring Upgrades

- Enhanced Performance

- Improved Safety

- Cost-Effectiveness

- Documentation

Industrial Robot Programming Services

Industrial robot programming services focus on developing, implementing, and optimizing control software that allows robots to perform tasks autonomously or semi-autonomously in industrial settings. These services cater to various industries, such as manufacturing, automotive, aerospace, and electronics.

Key Aspects of Industrial Robot Programming Services:

- Robot Selection and Integration

- Task-Specific Programming

- PLC Integration

- Sensor and Vision System Integration

- Collaborative Robot Programming (Cobots)

- Maintenance and Troubleshooting

- Optimization and Process Improvement

RLC to PLC Conversion

A control system that is designed by using relays is known as relay logic control (RLC). Similarly, a control system that is designed by using a microcontroller and other solid state switching devices is known as programmable logic control (PLC).Automates processes that would otherwise require manual intervention.PLCs can execute complex control algorithms for better performance.Provides continuous feedback on circuit parameters, enabling quick response to changes.Collects data for analysis, which can help in diagnostics and performance optimization.Easy to modify and update control logic without significant hardware changes.PLCs can handle multiple RLC circuits simultaneously, making it easier to expand systems.PLCs can detect anomalies in circuit behavior and trigger safety protocols.Facilitates remote monitoring and control, reducing risk for operators.

Key Aspects of RLC to PLC Conversion Services:

- Automation and Control

- Monitoring and Data Acquisition

- Flexibility and Scalability

- Improved Safety

- Integration with Other Systems

- Cost Savings

- Enhanced Troubleshooting

Annual Maintenance Contract

An Annual Maintenance Contract (AMC) is a service agreement between a provider and a client for the maintenance and support of equipment, machinery, or systems over a specified period, typically one year.

1.Comprehensive AMC

2.Scope of Services

3.Minimized Downtime

4.Regular preventive maintenance

5.Emergency repairs and troubleshooting

6.Technical support and advice.

Machine Reconditioning Work

Machine Reconditioning Work focuses on restoring and upgrading existing riveting machines to their original or improved working condition. This process ensures that the machine operates efficiently, accurately, and safely, which is crucial for industries where riveting is a key manufacturing process, such as aerospace, automotive, electronics, and metal fabrication. Reconditioning work can breathe new life into older equipment, extending its service life, improving performance, and reducing downtime.

Key Steps in Machine Reconditioning

- Initial Inspection and Diagnostics

- Disassembly

- Component Repair and Replacement

- Upgrading Control Systems

- Rivet Head Reconditioning

- Rewiring and Electrical Upgrades

- Lubrication and Maintenance

- Frame and Structural Reconditioning

- Safety System Upgrades

- Testing and Calibration

- Upgrading for Modern Applications

- Final Inspection and Certification

Siemens PLC Programming

Siemens PLC Programming involves developing and implementing control logic for Siemens Programmable Logic Controllers (PLCs), which are widely used in industrial automation. Siemens is a leading manufacturer of PLCs, with their most well-known product lines being the SIMATIC S7 series. Siemens PLCs are used in diverse industries like manufacturing, energy, automotive, and food and beverage for controlling machinery, processes, and automation systems.

Siemens PLC programming typically relies on SIMATIC STEP 7 software (or TIA Portal in newer systems) and follows IEC 61131-3 standard programming languages, such as Ladder Logic, Function Block Diagram, Structured Text, and others.