Applications

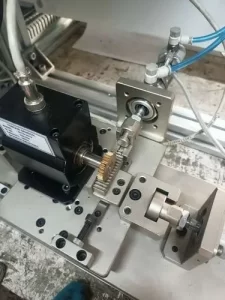

Special Purpose Machine

- Champaring Machine

- Laser Marking

- Measurement Testing Bench

- Axiel Flux Foarming Machine

- Salt Spray Testing Machine

- Painting Dust Collector

- Spray Painting Machine

- Paper Cushing

- Paint Booth

- Rim Cleaning

- Eclip & Circlip Machine

- Motor Winding Testing Machine

- Leakage Testing Machine

Hydraulic & Mechanical Press

- Rubber Moulding Press

- SM5 Press

- 1 to 1200 Tone Hydraulic Press Magnifacturing / Reconditional

- Reconditioning of old out dated PLC or RLC based Presses like Bruderer, SEW, Press Master, Erfurt Press, Kukong Press, Ocnad Press

- Troubleshooting of blanking line and blanking Press

- Stamping line Integration

- Foarming Press of Fiber glass Dies

- Hot Press Machine

Reconditioning

- Rubber Moulding Press

- SM5 Press

- 1 to 1200 Tone Hydraulic Press Magnifacturing / Reconditional

- Reconditioning of old out dated PLC or RLC based Presses like Bruderer, SEW, Press Master, Erfurt Press, Kukong Press, Ocnad Press

- Troubleshooting of blanking line and blanking Press

- Stamping line Integration

- Foarming Press of Fiber glass Dies

- Hot Press Machine

Jig Fixture Automation

Agriculture System Automation

In its simplest definition, automation farming covers all the practices that help with planting and harvesting with the aid of machines and other devices. These devices can be found on the farm itself, such as machinery to perform tasks more quickly and efficiently, or machines that help with precision and accuracy.

Spm Factory Automation Service

SPMs are also known as bespoke machines and specially designed machines. Also, as the name suggests, special purpose machines are crafted to deal with special tasks such as fulfilling mass demands, producing materials with complete automation and so on.

Automation For Mechanical Forging & Press

A mechanical press is a machine press that is primarily used for forming sheet metal and metal extrusion. The working principle of the mechanical press is to convert the rotational force from the electric motor to a translational force that drives the mechanism of pressing work

Mega Sand Filtration Plant Automation Get Latest Price

makes your water useable by treating the coarse sediments, particles, suspended solid matters, and substances causing blurriness in the water.When the pressure differential reaches its set control, a flush valve opens. This creates a low-pressure flow for the suction nozzles to then vacuum the debris from the filter.

Key Force Testing Machine Automation

Force Testing is a simple means of determining how easily an item will fail, break or actuate something and is the simplest type of material testing assessment that is imperative to the safety of the world around us and the objects we use. It is a way that manufacturers can measure the ease or difficulty of how something can be pushed, pulled, bent, compressed, cut, peeled etc.

Salt Spray Test Machine Automation

This testing machine contains a chamber where the saltwater solution is automized by utilizing the air pressure. It will lead to dense water fog inside the chamber. When the specimen will be placed inside the chamber then the rate of corrosion will be displayed through which it can withstand.

Conveyor System Automation

The main purpose of a conveyor system is to move objects from one location to another. The design allows for movement of objects that are too heavy or too bulky for humans to carry by hand. Conveyor systems save time when transporting items from one location to another

Rice Bag Packing System Automation

This automatic rice packing machine is mainly used for automatic quantitative packaging of grain,seed,granular, strips, block,and granular-powder materials,rice weighing and packaging machine can pack different materials, such as rice,wheat ,corn,Chinese medicine granular, melon-seed, salt, foodstuff,organic fertilizer

Bottling & Capping Plants Automation

A bottle filling system with PLC allows the user-defined selection volume in percentage which uses the ladder language. Ladder logic is used to control the process. The filling operation is based on the user-defined volume through which the user can choose the volume of liquid to be filled.

Automatic Tray Pusher System

Systems offers suitable solutions which are fully adapted to the weight and size of trays. Are you looking for a standard machine of a machine with a very high capacity? Do want to stack or de-stack trays, or a combination of both? Are you using the machine as a stand-alone or as part of a whole system? Are the input and output levels different? Whatever your requirements are, you will find a suitable solution . Please contact us for an exploratory conversation.

Batch Furnace Automation

Batch Furnaces refer to the method of heat treating – one “Batch” at a time, and thus the general design of the furnace itself. A Batch Furnace varies is size from the small “hearth” style that resembles a small pizza oven, to large “car bottom” furnaces that are literally use railroad sized cars on rails to move product in and out of the furnace.

Rotary Furnace Automation

A rotary furnace is a barrel-shaped instrument that is rotated around its axis when performing heat treatment. These instruments are tilted slightly to allow the sample under heat treatment to be passed from one end of the barrel to the other.

Continuous Hardening Tempering Furnace Automation

Consistency of quality is better obtained when components are continuously quenched, a few pieces at a time instead of in a batch at periodic intervals. Of the total tonnage of heat treated components the majority do not require fixturing and can tumble into a quench tank. The ideal plant for all such components in terms of quality, capital cost as well as operating cost is a continuous conveyorised heating and quenching system.

Conveyor Automation

By shuttling products to and from your packaging equipment via conveyor you reduce close interaction with these dangerous machines. This can improve packaging speeds and reduce the risk of collisions and decreased fuel use.